We handle product development, from A to Z

Conceptual design

with support of computer-based simulations

Prototype manufacturing

Extensive Testing

In laboratory and field

Isokinetic Sampling Meters

These meters are based on the concept of isokinetic sampling, which is a method developed to extract a known fraction of a multiphase stream flowing in a pipe, in a position where the multiphase mixture is well mixed and single phase velocities are uniform across the flow area.

This requires a careful design of the sampling section and of the method adopted to extract the sample.

VEGA

VEGA is a meter based on phase sampling.

The accuracy and rangeability of the VEGA meter can be extremely high.

The detection limit of the liquid volume fraction is many orders of magnitude smaller the the competitors.

DOME

Dual Orifice Isokinetic meter

DOME is based on the use of two flows restrictions placed in the same pipe cross section, immediately after a mixing section This method permits to extend the sampling concept to the full range of GVF.

iVIM

A low-cost gas-liquid meter

iVIM concept simplify the metering approach.

The meter based on a calibrated orifice and the measurement of the pressure gradient in a vertical pipe. iVIM can ben coupled with a sampling section to measure the Water-Cut.

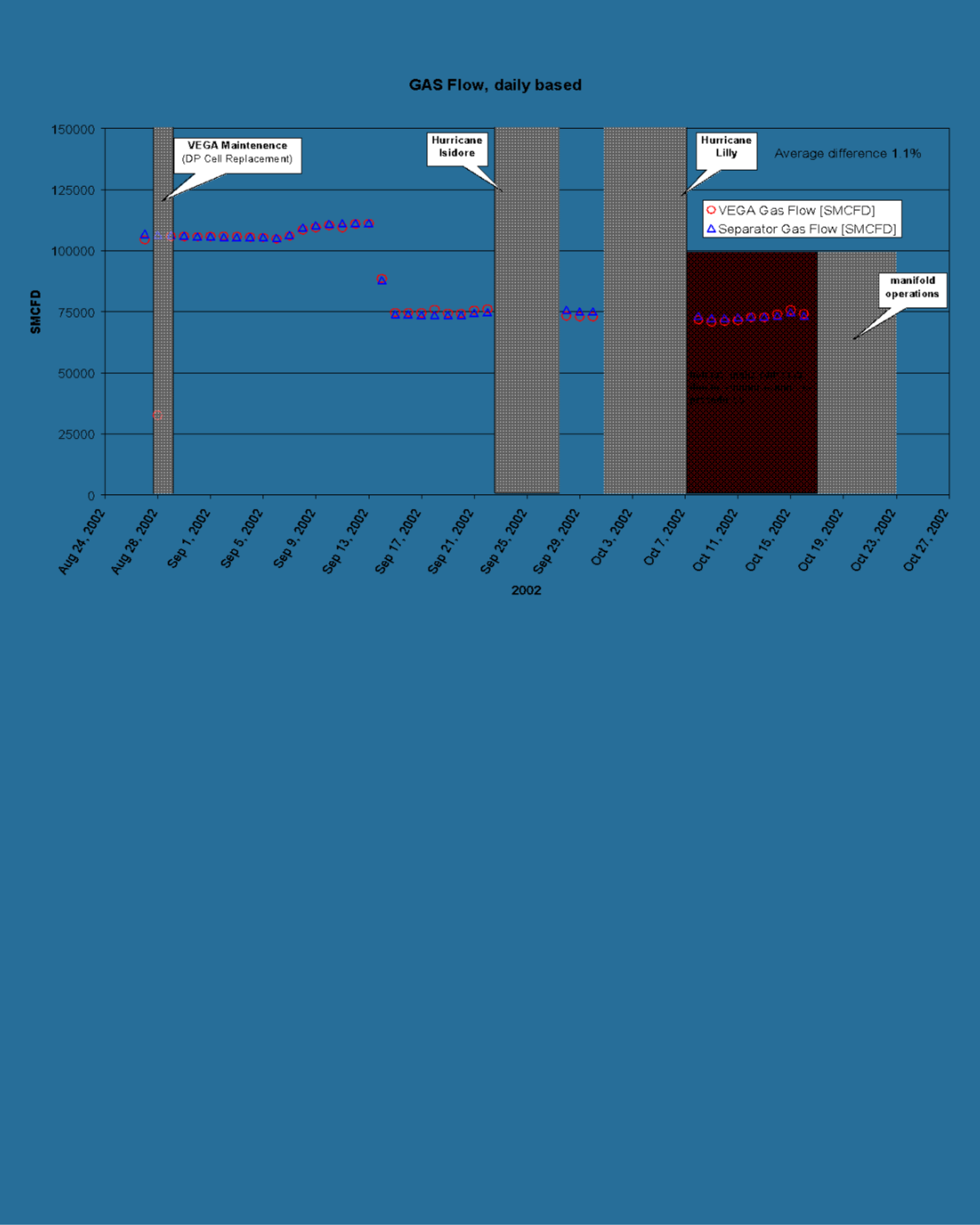

An innovative multiphase flow meter particularly suited for wet gas metering has been developed by TEA Sistemi in cooperation with ENI E&P. This meter type has been tested in the Trecate field in two sets of tests carried out in July 2000 and April 2001. The results obtained were excellent and the first commercial installation was completed in July 2002 on the Allegheny TLP in the GoM. To our knowledge this is the first installation worldwide of a three-phase wet gas meter not based on partial separation of the excess gas. In the present work we present the results obtained at the Trecate field and at the Allegheny TLP. Reference data at the Allegheny TLP was provided by allocation meters located on two separation vessels downstream of the Vega meter.

Software tool : MAST

What is MAST software ?

MAST is a one dimensional code that applies the multi-field approach combined with a high spatial resolution to simulate gas-liquid-liquid flow and flow pattern transitions in hydrocarbon transportation lines. The unsteady description of the slug flow allows the code to compute slug length distribution and frequency at any position along a pipeline, with no closure equations required for the slug bubble velocity and void fraction.

What are its capabilities?

- - Fully three phase flow model (oil/gas/water) including oil/water flow map to describe liquid/liquid systems

- - Single branch well/pipeline model including external mass sources (to simulate incoming branches)

- - Full network simulation capabilities

- - Valves models with PID controllers

- - Oil/gas reservoir simulations

- - Multiphase Pump and Separator models available for process system simulation

- - Chemical Inhibitors/ particle tracking models

Which modules are available ?

- - Valve/Flow Conditioner/Separator

- - Multi/Single Pigging

- - Complex Fluids

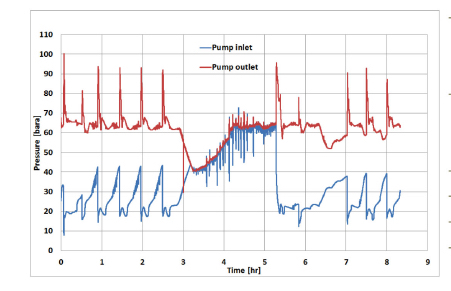

- - Multiphase Pump

- - Network

- - Tracers/Inhibitors

A solver of closure equations

MAST allows to adopt a set of default closure equations, select closures from a library and introduce customized closures.

Variable Asset Multiphase Ejector

What are ejectors ?

Ejectors are static machines in which a high pressure stream ( called Drive Stream) is used to boost a low pressure stream (Suction Stream).

- Simple design

- No moving Parts

- High degree of reliability

- Low cost

- Low efficiency

- Low rangeability

From Conventional Ejectors...

Internals or overall machine replacement after one year of operation (on average)

due to continuous evolution of well performances during production life (GOR and WC increase, well depletion, etc.).

... to VAME

Geometry (nozzle and mixing chamber) can be varied during operation as well as performance varies.

No requirement for equipment or internal replacement.

BASIC FEATURES

- No operative costs

- No maintenance costs

- Payback period: few weeks / few months

- Low impact on existing equipment

- Environmental benefits - zero emissions

- Proven reliability

APPLICATIONS

- Boost the pressure of LP wells

- De-bottleneck compressors

- Down-hole as gas lift aid

- Well revival, clean-out, kick-off

- Boost the pressure of process gas

- Backpressure reduction to increase production from wells