HSE & Risk Services in Oil & Gas /Process Industry

Risk Analysis

Vapour Cloud Explosions and Major Fires on onshore/offshore facilities represent a significant risk to be managed due to the relevant impact on personnel safety and business continuity. TEA Sistemi developed in-house codes, supported by semi-empirical models or advanced CFD calculations to analyse release behaviours for high risk releases and combine them with a dedicated frequency analysis (release frequencies, weather data, ignition probabilities) to provide quantitative risk features for people QRA (i.e. LSIR, IRPA, PLL) for assets FERA (i.e. Thermal & Blast Load Analysis, Exceedance Curves) and for Escape & Evacuation purposes: EERA and TR Impairment studies.

Technical Safety

TEA has gained large experience in Technical Safety activities , to support process engineering, permitting and integrated risk management strategies. The following tasks are a typical part of day by day activities:

- Technical Safety Workshops: PHA, HAZOP, HAZID, SIL

- Fault Tree Analysis (FTA) for well operations and O&G/ chemical plant design

- Failure Mode & Effects Consequence Analysis (FMECA)

- Simultaneous Operations (SIMOPS) Risk Assessment & Workshops for Construction &Well Operation activities

- ALARP Assessment and Workshops to support ALARP Demonstration

Advanced Modelling Computational Fluid Dynamics

Compliance with EU Directive 2013/30/EU (offshore O&G safety)

SECE and Performance Standards

NaTech Risk Assessment & Management

About risk analysis

TEASistemi knowledge in multiphase and process technologies have been extensively used to provide the following service to industry:

- QRA / FERA

- Safety Design

- Fire Fighting

- Technical Safety Support

- Support to Permitting & Compliance

- Site Remediation

RAINBOW Project (Risk Assessment In a BlowOut)

Well blowouts are one of the most important accidents related to exploitation of hydrocarbons.

These events consist in uncontrolled release of fluids and the consequent generation of high velocity gas jets carrying entrained liquid droplets at appreciable height to ground or into the sea.

Relevant HSE risks may be associated to blowout events, whit risks for the operators, third parties

as well as environmental and reputational impacts.

Thanks to a decennial R&D activity under, Eni S.p.A. sponsorship TEA Sistemi has developed an

integrated approach for the risk analysis of a blowout event.

TEA Sistemi carried out, for each operative areas specific R&D activities under both external sponsorship and internal research programs.

In this framework TEA makes available to the Clients the following resources:

- Computational Fluid Dynamic. Wide experience in a large range of application of CFD technology using the most important CFD tools like FLUENT, Star-CD, MIKE21, etc.

- Experimental activities. TEA is a rather unique company in the Italian outline as it runs a fully equipped multiphase flow laboratory with relevant capabilities. The laboratory is used for experiments within R&D programs committed or internally supported, as well as for factory acceptance tests.

- Extensive relationship with the academic world, both in Italy and worldwide.

Thanks to a decennial collaboration between Eni SpA and TEA Sistemi, RAINBOW, an integrated approach for the analysis of a blowout event, has been developed.

The consolidated RAINBOW framework incorporates state of art modelling validated against experimental and/or numerical data obtained from real blowouts cases or simulated laboratory experiments.

In general, RAINBOW methodology proposes three different approaches, which may be adopted to study a blowout:

- Best Estimate Approach carrying out detailed analyses of all the blowout phases with a high level of accuracy (CFD studies usually support this approach) on the blowout effects

- Standard Approach carrying out analyses using simplified modelling embedded into commercial software for simulating the blowout effects

- Short-Cut Approachcarrying out analyses by parametric systems (e.g. tables and graphs) for a quick evaluation of the blowout effects

Finally it is noted that in some instances, the RAINBOW methodology, can be applied also to buried pipeline releases.

The typical RAINBOW methodology applications are the following:

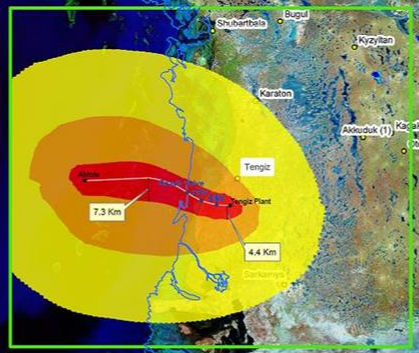

- Offsite Quantitative Risk Assessment studies

- Permitting activities

- Emergency Response Plan (ERP) preparation

- Oil Spill Contingency Plan (OSCP) preparation

- Field layout assessment (e.g. zoning, well location, etc.)

- Wells killing optimization (e.g. relief well location, killing design)

- Support to real or simulated emergency phases

In the last 20 years (see also figure below) about Blowout 200 studies have been performed with RAINBOW. The project was awarded the technological award by the R&D department of Eni SpA.